New Design Multifunction Punching and Comb Wire Spiral Coil Binding Machine(SUPER4&1)

| Categories | more |

|---|---|

| Brand | SUPU |

| Model | SUPER4&1 |

| Condition | New |

| Product Type | Electric changable die punching machine |

| Processing Type | Binding Machine |

| Dimension(L*W*H) | 500x600x400mm |

| Binding machine | Multifunction binding machine |

| Material | Aluminum |

| Continual punch pages | 2500 pages/minute ~ 3000 pages/minute |

| Punch width | 297MM |

| Electromotor power | 200W |

| Power supply | AC220V-240V 50Hz |

| Unit Price | US $ 1500-1800 / piece |

| FOB port | ningbo/shanghai |

| Terms of Payment | T/T, Western Union |

| Update Time | Apr 24,2025 |

New design multifunction binding machine with comb wire spiral coil and punching SUPER4&1

PRODUCT DESCRIPTION

One machine with four function: Punching, comb binding, wire binding, spiral binding

Punching dies can change easily, by rock switch on right of machine

Contain 4 different punching dies. 4 different hole type

This machine combine 4 function into 1 machine, more comvenient, less space Very suitable for print shop, print industry, even factory For book binding punching, notebook. File Good quality, metal material, one machine weight 100kgs

FEATURES

Electric punching and binding by the footpedal.

Punch capacity: Up to 22000 sheets of 20 lb paper for an hour Punching up to 30-35sheets each time

Can punch A4 A3 SIZE paper Fully disengageable pins

Adjustable depth margin Punching margin &side margin is adjustable

Heavy duty motor and gearbox With comb binding, wire closing, coil inserting Interchangeable punch die by manual revoving or electric revolving.

International patent design

All metal construction makes it durable and many years free With CE, CETL. SAA certification

Punching 2: 1, 3: 1, 4: 1(5: 1), Comb, Calendar

With wire closer, calendar binding, coil feeder and comb binding

TECHNOLOGY DATA

| Item | Plastic comb | Double wire (2:1&3:1) | Spiral(Oval) (4:1) | |

| Punching thickness of sheets | 25sheets(70 g) 20sheets(80g) | 25sheets(70 g) 20sheets(80g) | 25sheets(70 g) | |

| Punching thickness of PVC Cover | 4 sheets(0.2mm) | 4 sheets(0.2mm) | 4 sheets(0.2mm) | |

| Punching thickness of 230g Cover | 4sheets | 4sheets | 4sheets | |

| Binding thickness | 4.5mm~51mm | 15.9mm~32mm(2:1) 4.8mm~14.3mm(3:1) | 4.5mm~50mm | |

| Punch width | 297mm | |||

| Die disengagement pin | Full(21 pins) | Full 2:1(23 pins) 3:1(34 pins) | Full (47 pins) | |

| Punch margin adjustable | 2mm~6mm | |||

| Continual punch pages | 2500 pages/minute ~ 3000 pages/minute | |||

| Power supply | AC220V-240V 50Hz | |||

| Electromotor power | 200W | |||

| Machine dimension | 612mmx510mmx394mm | |||

| Machine wight | 90KG | |||

INSTRUCTIONS FOR INSTALLATION AND ADJUSTMENT 1,Place the machine on workbench after opening the case, make sure it is steady on four feet. Connect the power socket and foot pedal joint 2,Assemble comb binding handle, wire binding handle to make it is nearly 90°to the top of base and then assemble the lock handle and die-changing handle and make the lock handle stay at the lock up position .

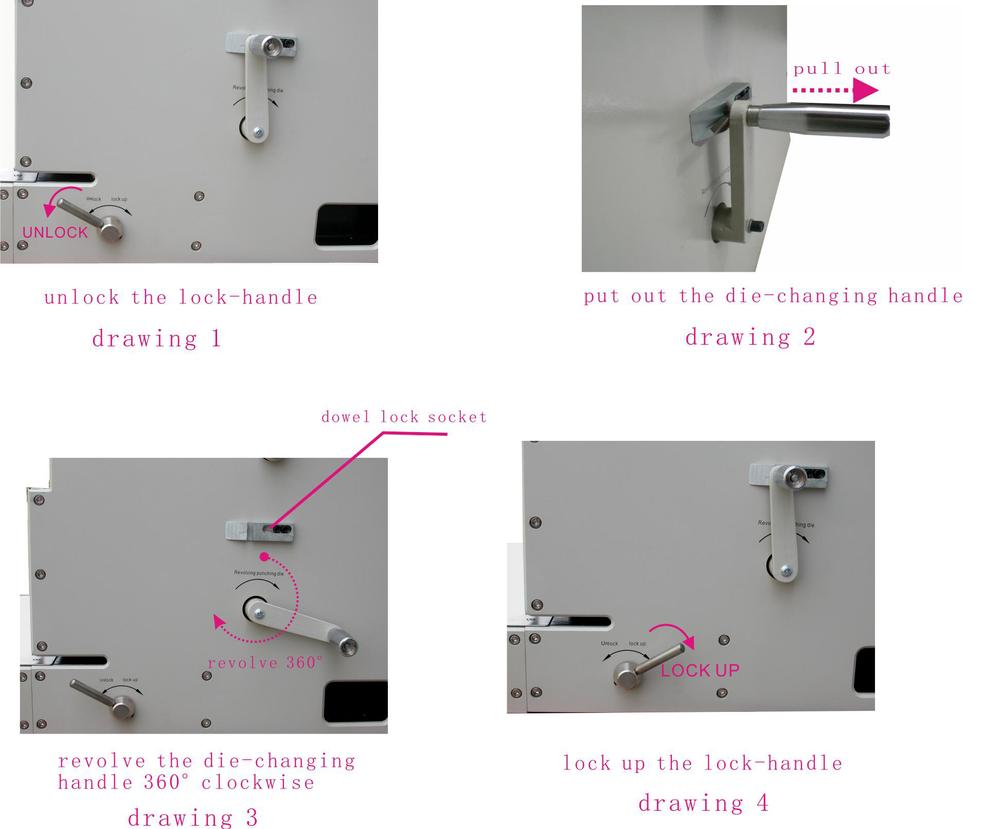

METHOD AND PROCEDURE TO CHANGE PUNCHING DIE 1,Cut off power supply, unlock die locking-handle ( See above drawings )

2,Pull out the Die-changing handle while revolving it 360°clockwise.

3,Release the Die-changing handle and lock up the Lock-handle

METHOD AND PROCEDURE TO PUNCH

1.Following above method to choose right punching die 2.Accroding to the paper's size, adjust side margin and paper fixer to suitable position. 3. Turn on power and try to put little paper and then treat the foot pedal to do a testing .

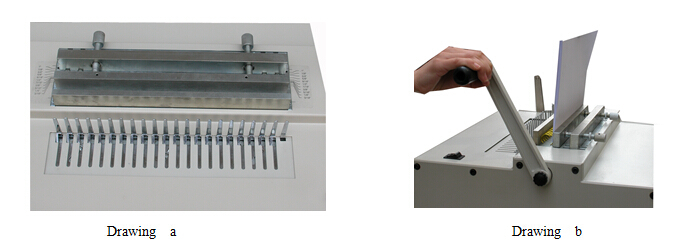

a)Operation instructions and use method for double wire(2:1,3:1) 1,Choose right punching die for double wire (2:1 or 3:1). According to paper's size choose paper fixer and side margin controller. Insert paper then treat foot pedal to finishing punching. 2,Adjust two adjustable knobs according to size of wire 3,Closing the wire by using the closing handle .

b) Operation instructions and usage for Spiral 1,Choose the right punching die for Spiral. According to paper's size choose paper fixer and side margin controller. Insert paper then treat foot pedal to finishing punching. 2,Inserter the coil to the punched sheets by handle in the first circles then press roller button to make roller run then lean the coil against the roller to make it inserting automatically . 3,Cut and crimp the coil with plier attached with machine ,completing the binding

c) Operation instructions and usage for comb 1,Choose the right punching die for comb. According to paper's size choose paper fixer and side margin controller. Insert paper, then treat foot pedal to finishing punching. 2,Place plastic ring in back of comb with opening upward, pull down the binding handle clockwise to open the comb . 3,Place the punched sheets into the comb then push the binding handle upward counterclockwise to finish binding . 4,If sheets need to be increased or decreased follow step 2.After it follow step 3 to binding

POINTS FOR ATTENTION

1.Power supply should meet requirement of the machine. 2.Cut off power supply when change punch die to prevent accidents by mistake and unnecessary loss. 3.Punch thickness should not be exceeded according to the manual. Adhesive material is forbidden in case of blade damage.

ELECTRIC APPLIANCE

1,Turn on power switch before starting the machine. Indicator light should be on. 2,Put paper into the punching slot and put your foot on foot pedal. The machine's punching pins move up and down one time while eaching treating the footpedal .

WARM SUGGESTION

1. To make perfect punching effect and long time usage , please do not punch exceed the capacity on the illustration of each punching die .

2. While punching 230g cover ,please do not punch more than 4 sheet .Thanks .

WORKSHOP

EXHIBITION

CERTIFICATION

- Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

- Name:

- Lois

- Tel:

86-571-88963506

- Email:

- marketing@hzsuper.com

- Skype:

- Skype:supubinding

- Address:

- Jingda Road,Shanlian Development Zone,Sandun,Hangzhou,China,310030