Leading brand in china's Business equipment manufacturer

Home / All / Binding machine / Wire Binding Systems /

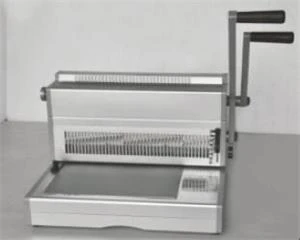

SUPU Separate Wire Punching And Wire Closing Machine Model CW330

SUPU Separate Wire Punching And Wire Closing Machine Model CW330

| Categories | Wire Binding Systems |

|---|---|

| Brand | SUPU |

| Model | CW330 |

| Power | manual |

| Width | 330mm |

| Pitch | 8.47mm |

| Hole type | square, round, oval |

| Punching thickness | 25sheets |

| Binding Thickness | 143sheets |

| Number of punch pins | 38 |

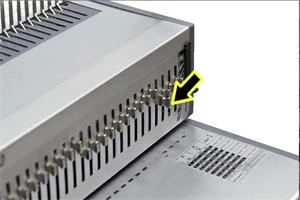

| Disgagement punch pins | 38 |

| FOB port | SHANGHAI OR NINGBO |

| Terms of Payment | L/C, Western Union, T/T |

| Update Time | Apr 24,2025 |

Detail Information

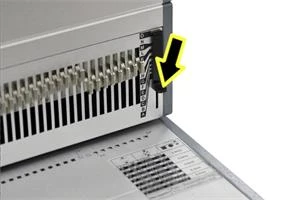

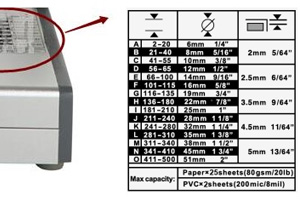

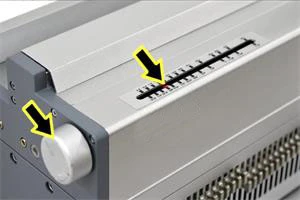

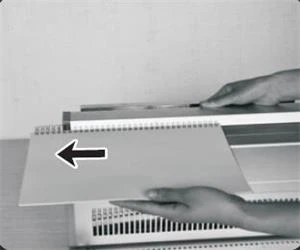

Document measure to determine which comb size to be used All aluminium construction make it durable and many years worry free High capacity waste container requires emptying less frequently

Related Products

Please send your message to us

- Tel

- *Title

- *Content

Just tell me what you want, a customized product is welcome!

navigation

Contact Person

- Name:

- Lois

- Tel:

86-571-88963506

- Email:

- marketing@hzsuper.com

- Skype:

- Skype:supubinding

- Address:

- Jingda Road,Shanlian Development Zone,Sandun,Hangzhou,China,310030

subscription

QR code